-

BM111 has multiple fiber interfaces such as QBH, QD, G5, etc., which can be adapted to various mainstream lasers. 3 protective lenses, efficient protection of collimation and focusing lenses, automatic focusing, reducing human intervention, focusing speed 170mm/s, adjustment accuracy 0.05mm

-

The CypCut system is easy to use, rich in functions, stable and reliable. The software has built-in nesting function, as well as advanced functions such as "traceless micro-joining", "inductive perforation", and "disc centering" to meet various processing needs.

-

Main features of CW spindle chiller:

1. Heat dissipation 50W/℃;

2. Small heat dissipation chiller; high efficiency and energy saving, long life and durability, easy to operate.

3. With water flow alarm and ultra-high temperature alarm function;

4. Multi-national power supply specifications; ISO9001 certification, CE certification, RoHS certification, REACH certification.

-

STEEL STRUCTURE INDUSTRY

Cut the steel structures needed for small and medium-sized buildings, stadium stands and canopies, small warehouses, etc.

-

KITCHENWARE INDUSTRY

Stainless steel gas stoves, stainless steel stoves, stainless steel ovens, etc. are all processed using laser cutting machines

-

MEDICAL INDUSTRY

Laser cutting applications in medical device manufacturing include: manufacturing stents, heart valves, medical tools and equipment components

-

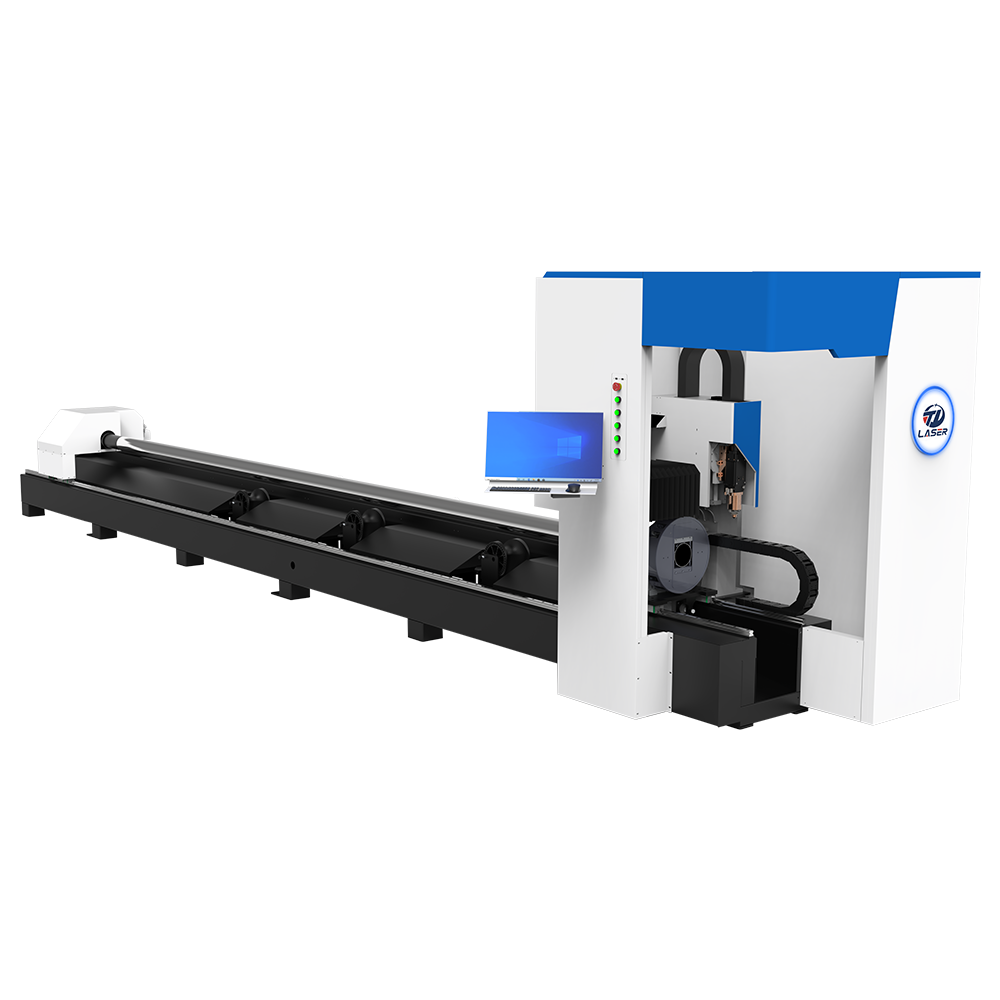

FITNESS EQUIPMENT

Bicycles, spinning bikes, children's scooters, sit ups, and other products all use a large number of tube components.

-

AVIATION

Due to its high precision, fast processing speed, low thermal shock, and no mechanical effects, laser cutting is applied in many aspects of aircraft engine manufacturing.

-

WIND POWER GENERATION

Carbon fiber laser cutting technology enables carbon fiber sheets to be accurately formed into various shapes to meet various needs. Carbon fiber board also has corrosion resistance and high temperature resistance, allowing wind turbines to operate stably in corrosive and high-temperature environments