laser welding handheld machine is a kind of equipment that uses high energy density laser beam for welding.

Laser welding handheld machine is mainly composed of laser generator, optical fibre, handheld welding gun, cooling system and other parts. The laser generator is the core component, providing the energy required for welding. The optical fibre is used to transmit the laser. The handheld welding gun facilitates the operator to flexibly weld work pieces in different positions. The cooling system, on the other hand, ensures that the equipment does not overheat during the working process and maintains normal operation.

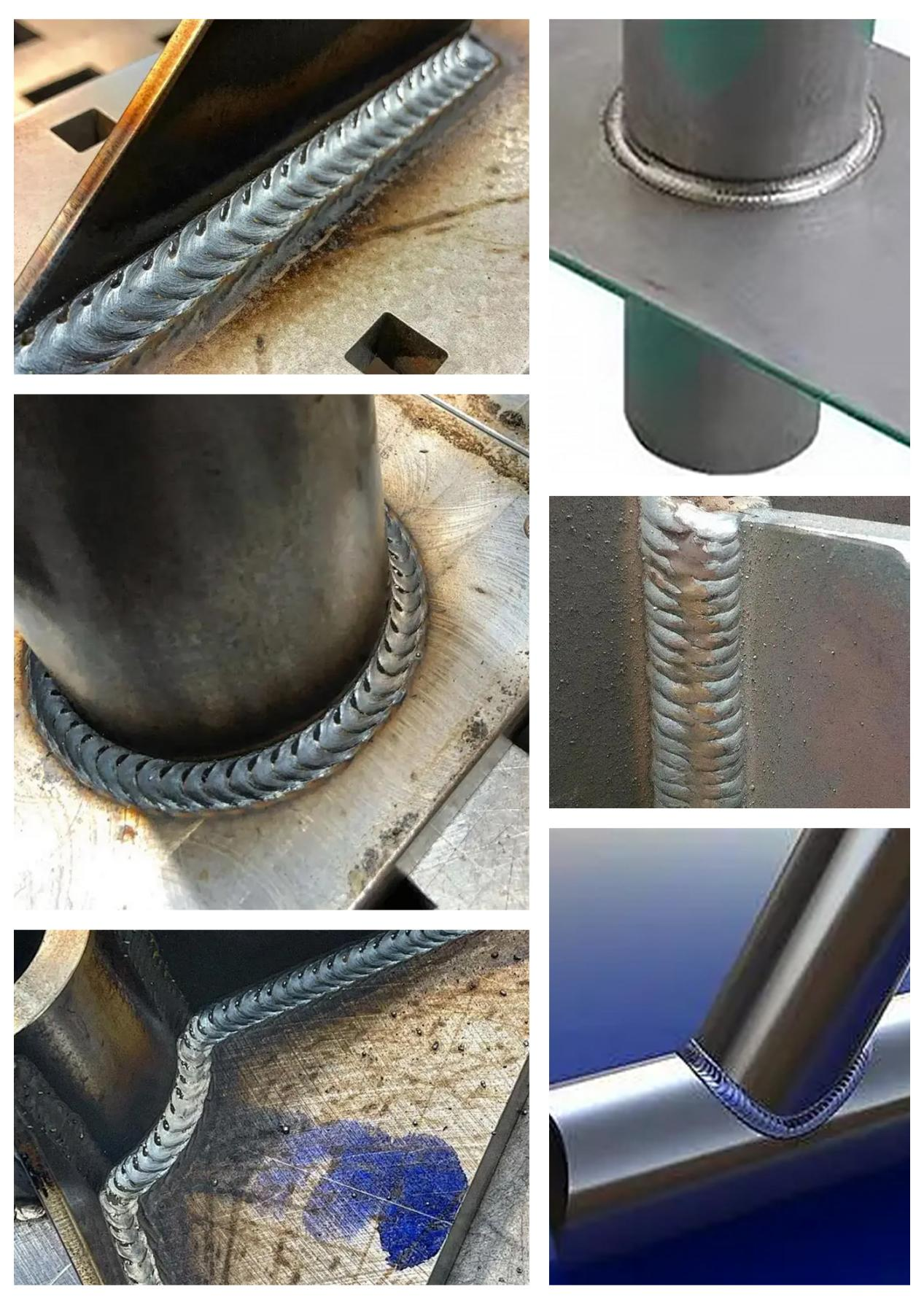

Mini steel welding machine has high welding precision. It can precisely control the welding position and depth. Secondly, the welding speed is fast. Compared with the traditional welding method, the working efficiency can be greatly improved. And it has a small heat-affected zone, which does not subject the work piece to heat deformation over a large area. At the same time, the operation is relatively simple. Operators can use it after some training.

Model | TDLW |

Laser Power | 1000W,1500W,2000W,3000W |

Voltage | 220V 50/60HZ |

-

LASER SOURCE

MAX laser adopts modular design, the optical module integrated fully enclosed design. The output spot is stable and the power stability is strong. It has the advantages of good welding effect and high consistency. Widely used in laser welding, laser cladding, laser brazing, laser surface heat treatment.

-

HANDHELD WELDING GUN

Multi-point temperature measurement, real-time monitoring: self-developed safety detection system, real-time monitoring of multiple temperature points inside the fuselage

Dustproof, drop-proof, anti-interference: self-developed safety detection system, real-time monitoring of multiple temperature points inside the fuselage, efficient and convenient

Focusing mirror and protective mirror are drawer-type, easy to replace. Collimating mirror and QBH are integrated, easy to replace on site -

WIRE FEEDER

Four-wheel dual-drive wire feeding mechanism/supports continuous wire feeding and pulse wire feeding modes. Wire feeding speed adjustable from 15-600cm/min.

Wide range of applications, matching many types of products. Cost-effective with both efficiency and portability. -

WATER CHILLER

Can choose environmentally friendly refrigerant; temperature control accuracy of ± 0.5 ℃; with two temperature control modes, suitable for different occasions, there are a variety of settings and fault display function.

With a variety of alarm protection functions: compressor delay protection; compressor overcurrent protection; water flow alarm; temperature over/under alarm.

Multi-country power supply specification; ISO9001 certification, CE certification, RoHS certification, REACH certification.

Stable cooling and easy operation. Optional heater and water purification configuration.

-

AUTOMOBILE MANUFACTURING INDUSTRY

Used for body welding, such as connecting car doors, roofs, and other components

-

THE METAL PROCESSING INDUSTRY

Used for welding doors, windows, kitchen utensils, etc

-

THE ELECTRONIC EQUIPMENT MANUFACTURING INDUSTRY

Metal casing and internal structural components of weldable electronic devices

-

ADVERTISING AND DECORATION INDUSTRY

Used in the production of metal characters, welding its strokes and contours.

-

HARDWARE INDUSTRY

Used in the manufacture of hardware tools (e.g. pliers, spanners) and small hardware products (e.g. hinges, locks).

-

MEDICAL INSTRUMENT INDUSTRY

Welding of metal surgical instruments (scalpels, tweezers, etc.)